Essential Guidelines for Proper Safety Lanyard for Harness Use in Fall Protection

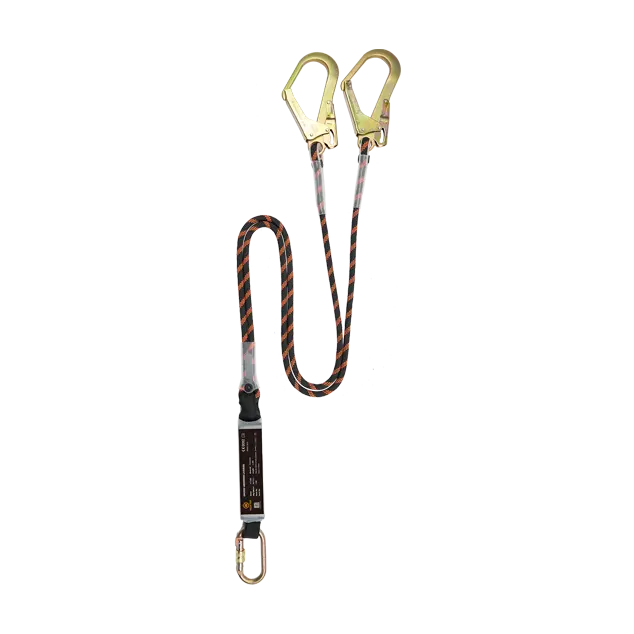

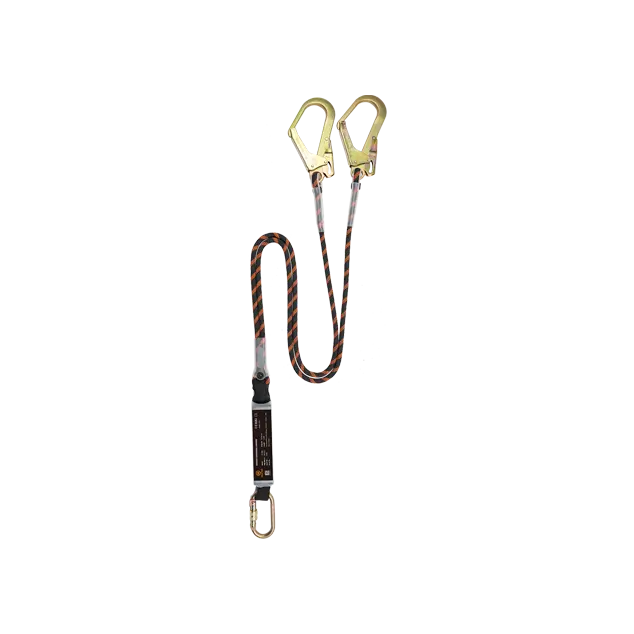

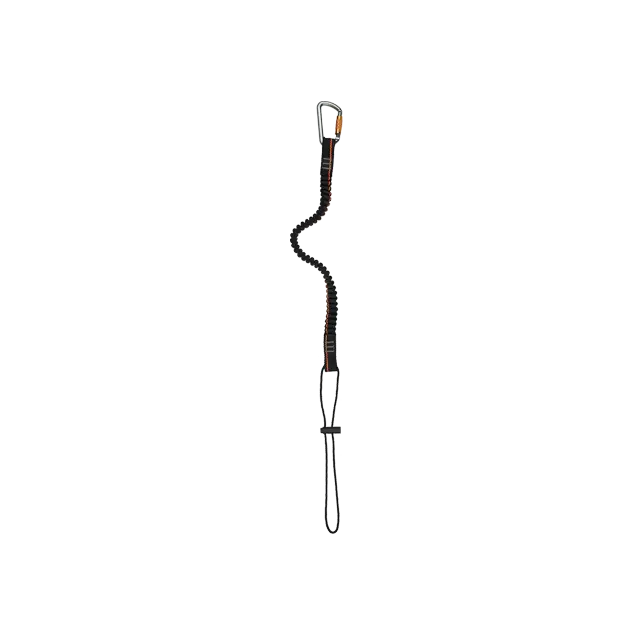

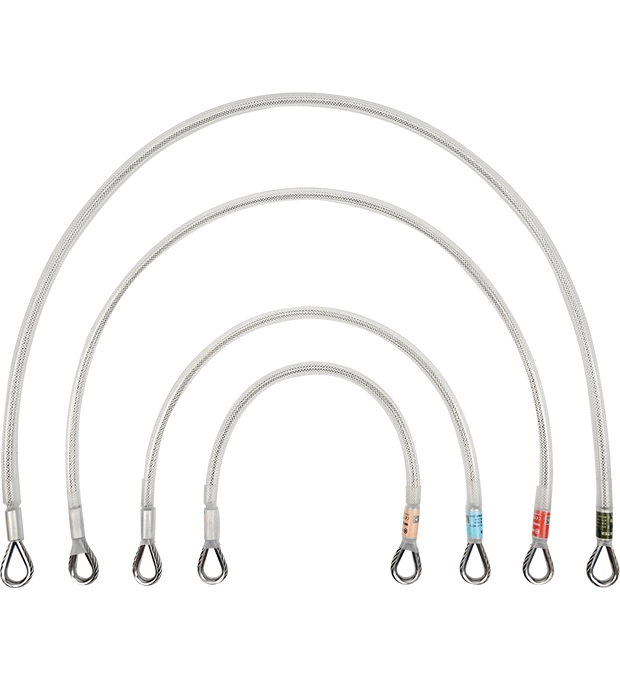

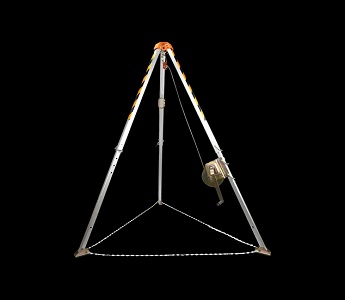

Proper training in fall protection systems and awareness of potential hazards are essential for workers. At HOATER, we offer fall protection harnesses and devices to ensure worker safety. For lanyard usage, start by selecting the appropriate lanyard based on the anchor point height and ensure proper attachment. If the safety lanyard has a deceleration device, attach it to the D ring; if it is retractable, attach the casing to the anchor point. Always verify that the lanyard has never been deployed and follow all manufacturer guidelines and additional safety steps. Putting on a safety harness is a crucial initial step in using a personal fall arrest system, but it is often prone to errors. To use a safety harness correctly, begin with a thorough inspection for wear and tear on straps, fittings, buckles, and grommets, and check the last inspection date. Orient the harness by holding the D ring, then secure the leg straps, shoulder straps, and chest strap, ensuring no twists are present.

The Importance of Safety Lanyard Manufacturers' Tags

What is a Safety Lanyard Manufacturers' Tag?

A safety lanyard manufacturers' tag is an essential element that guarantees the reliability and safety compliance of the equipment. It clearly displays the CE standard, which ensures adherence to European safety requirements. The tag provides critical information such as the weight capacity, typically ranging from 60 to 140 kg (approximately 130 to 310 lbs), and specifies the type of safety lanyard. This includes details on a data card, such as the product name, model number, material, size, style, date of manufacture, serial number, and class designation, which indicates the intended application of the lanyard (e.g., fall arrest, suspension, limited access, ladder climbing, or worker positioning).Some tags also feature a USER ID box for adding personalized identification numbers or names. Tags include an inspection grid to record regular inspections, which is essential for maintaining the lanyard's safety performance and functionality.

How to Read a Safety Lanyard Manufacturers' Tag

First, look for the CE standard prominently displayed on the tag, such as EN 355 or EN 354, which indicates that the lanyard meets specific European safety requirements and lists the weight capacity. Next, examine the data card for detailed information, including the product name, model number, material, size, style, date of manufacture, serial number, and class designation. Pay close attention to any warnings on the tag, as they are crucial for safe use. Check the maximum capacity listed on the tag, which includes the combined weight of the worker, clothing, and tools, ensuring it conforms to CE safety limits. Finally, use the inspection grid to record inspection dates, which is essential for maintaining the lanyard’s safety and functionality. For more detailed information, always refer to the user manual or contact the manufacturer’s customer service.

EN

EN

fr

fr